To fast-track its breakthrough pulse charging technology toward commercialisation, TAE Power Solutions needed continuous 24/7 battery testing with zero tolerance for safety risks, data loss, or operational delays. ODOS’ Decalog system was live within hours, delivering real-time monitoring, instant anomaly alerts, complete remote control for engineers across the UK and Europe, and guaranteed data capture even during outages. The result: 100% uptime, faster iteration, seamless cross-team collaboration, and the robust, high-integrity data needed to prove performance and move decisively ahead of the competition.

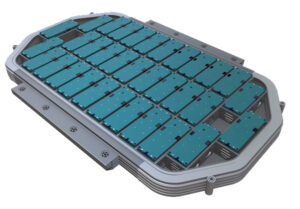

TAE Power Solutions, a division of TAE Technologies, is advancing pulse charging technologies designed to significantly improve the way lithium-ion batteries are charged. As part of its early-stage research and development, TAE initiated a proof-of-concept programme to validate the performance and safety of its systems across a wide range of battery cell chemistries and configurations. Given the experimental nature of the work, the company needed a way to monitor around-the-clock test rigs in real-time, ensure safety through rapid anomaly detection and capture comprehensive data for iterative development and future commercialisation.

TAE Power Solutions faced several critical challenges in the early stages of validating its pulse charging technology. The inability to continuously monitor test rigs running 24/7 without manual intervention posed a significant risk to both safety and data integrity. Without a real-time alerting system, identifying anomalies or system failures in time to prevent damage was nearly impossible.

Additionally, the lack of remote control capabilities limited the engineering team’s ability to manage systems off-site, increasing the operational burden. Compounding these issues was the risk of data loss during network outages, which threatened to undermine the validity of their trial results, particularly concerning for a project heavily dependent on high-fidelity data to demonstrate proof of concept across various battery cell chemistries.

ODOS deployed its Decalog system alongside a real-time dashboard solution to support TAE Power Solutions’ pulse charging infrastructure. This deployment enabled full remote monitoring, secure logging, automated alerting and cloud-based data access, all essential for evaluating the efficiency and safety of the pulse chargingsystem.

Real-time alerts enabled instant identification and mitigation of system anomalies. Remote access and control functionality allowed engineers to monitor and intervene from any global location. Even in the event of network outages, data was safely logged and synced once connectivity was restored. The intuitive dashboard design allowed both technical and non-technical users to visualise and download key performance data, enhancing collaboration across distributed teams.

TAE’s engineering team collaborated closely with ODOS to configure and install the Decalog system. Once connected to the prototypes and relevant software libraries uploaded, the Decalog system was operational within hours.

The dashboard was customised to monitor safe operating thresholds, track performance data and enable remote control functionality. With engineers based across the UK and Europe, the seamless access enabled the team to maintain operational oversight regardless of physical location.

The implementation aligned with rigorous safety and traceability standards, crucial for R&D-stage energy technologies.

Achieved 100% system uptime across continuous 24/7 test cycles, enabled by real-time system monitoring and proactive alerting mechanisms that allowed engineers to immediately identify and resolve operational issues before they escalated.

Enabled full remote access and control, allowing engineers and stakeholders located across the UK and Europe to manage and interact with the test rigs without needing to be on-site, improving flexibility and reducing logistical constraints.

Guaranteed data integrity through offline logging, ensuring that all data generated during network outages was safely stored locally and automatically synchronised once connectivity was restored – eliminating any gaps in critical test data.

Delivered rapid deployment timelines, with the system becoming fully operational within a matter of hours from initial setup, allowing TAE to maintain momentum in their fast-paced R&D environment.

Provided seamless multi-format data export, supporting efficient offline analysis, simplified stakeholder reporting, and easier data sharing across technical and non-technical teams.

Increased confidence in trial outcomes, as the robust data logging and integrity mechanisms reassured engineers that results reflected real system performance, even under diverse operating conditions and battery chemistries.

Enhanced safety protocols, with real-time monitoring, automated alerts, and the ability to issue immediate remote shutdown commands when anomalies were detected, significantly reducing potential risks to equipment and personnel.

Accelerated iteration and development cycles, as instant access to performance data allowed engineers to make informed adjustments quickly, improving the pace and agility of experimentation.

Improved cross-team collaboration, with ODOS’ centralised dashboard enabling geographically dispersed team members to access the same live and historical data sets – creating a shared source of truth for decision-making.

Reduced on-site intervention requirements, thanks to remote access and control features that allowed issues to be addressed without the need to physically access the facility, improving efficiency and reducing operational disruption.

”We’re only using a fraction of what the ODOS system can do – but it’s already giving us everything we need to move faster with confidence.”

Ruben Graca, Battery Build and Test Operations Manager, TAE Power Solutions.